PRO-515 Parts Adjustment

Parts adjustment for conveyor adjustment, conveyor height adjustment, wrap around belt adjustment, and label press piece adjustment

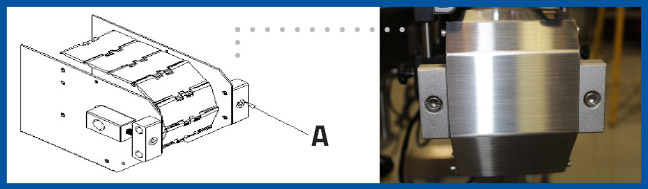

1. Conveyor adjustment: To adjust the tension of the conveyor belt, loosen the two nuts on the screws. Turn counter clockwise to loosen and clockwise to tighten. Make sure the conveyor is centered to reduce any noise. See A.

- Wrap Around Belt

- Pressure Plate

- High & Low Adjust

- High & Low Adjust

- Frontward & Backward Adjust

3. To adjust wrap around station height: only adjust screw C and D so you can adjust wrap around belt and pressure plate height.

4. To adjust wrap around station widths: As follow drawing show, put object between wrap around belt and pressure plate. Adjust frontward and backward screw E, let pressure plate press object with suitable pressure. Then turn on conveyor to check object and be turned smoothly.

5. Wrap around belt adjustment: To adjust the tightness and centering the belt, adjust the screw A. When adjusting, use only small increments and let the belt run for a while to determine the final position. A belt that is not centered will slip up or down.

6. Paper press piece adjustment: First, loosen screw (A) turn the rod (2) counter clockwise and hold it. Use your other hand to tighten screw A and then release it.

7. Object Sensor: The object sensor is a fiber optic infra-red sensor use to detect the presence of bottle on the labeling zone. If the sensor is not able to detect a bottle, adjust the intensity of the amplifier until the sensor is able to trigger the applicator to apply a label.