PL-501 Label Applicator

Follow these instructions to insert the labels into the label applicator

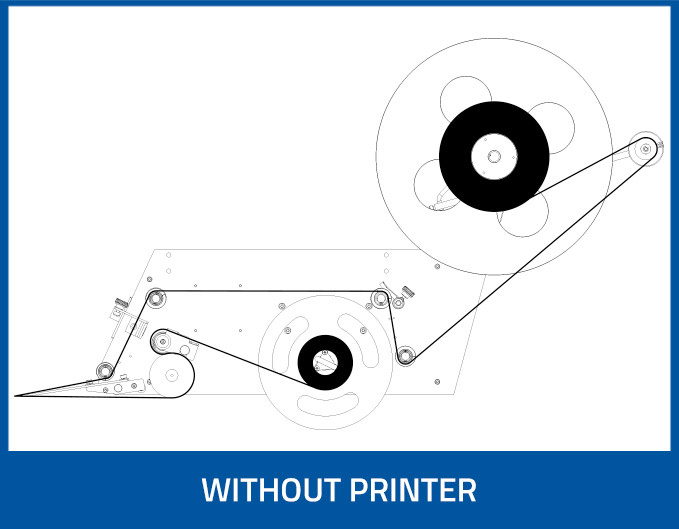

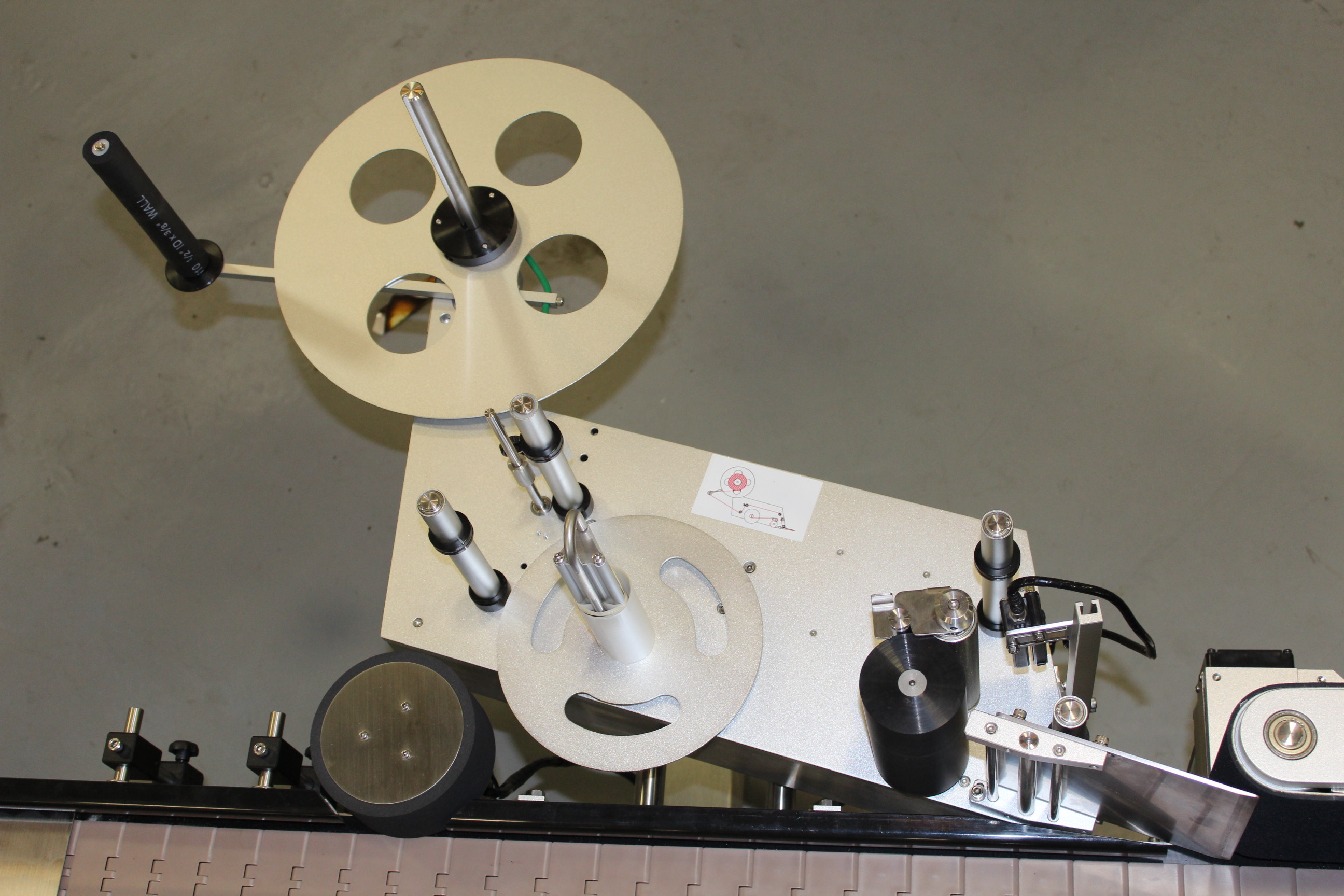

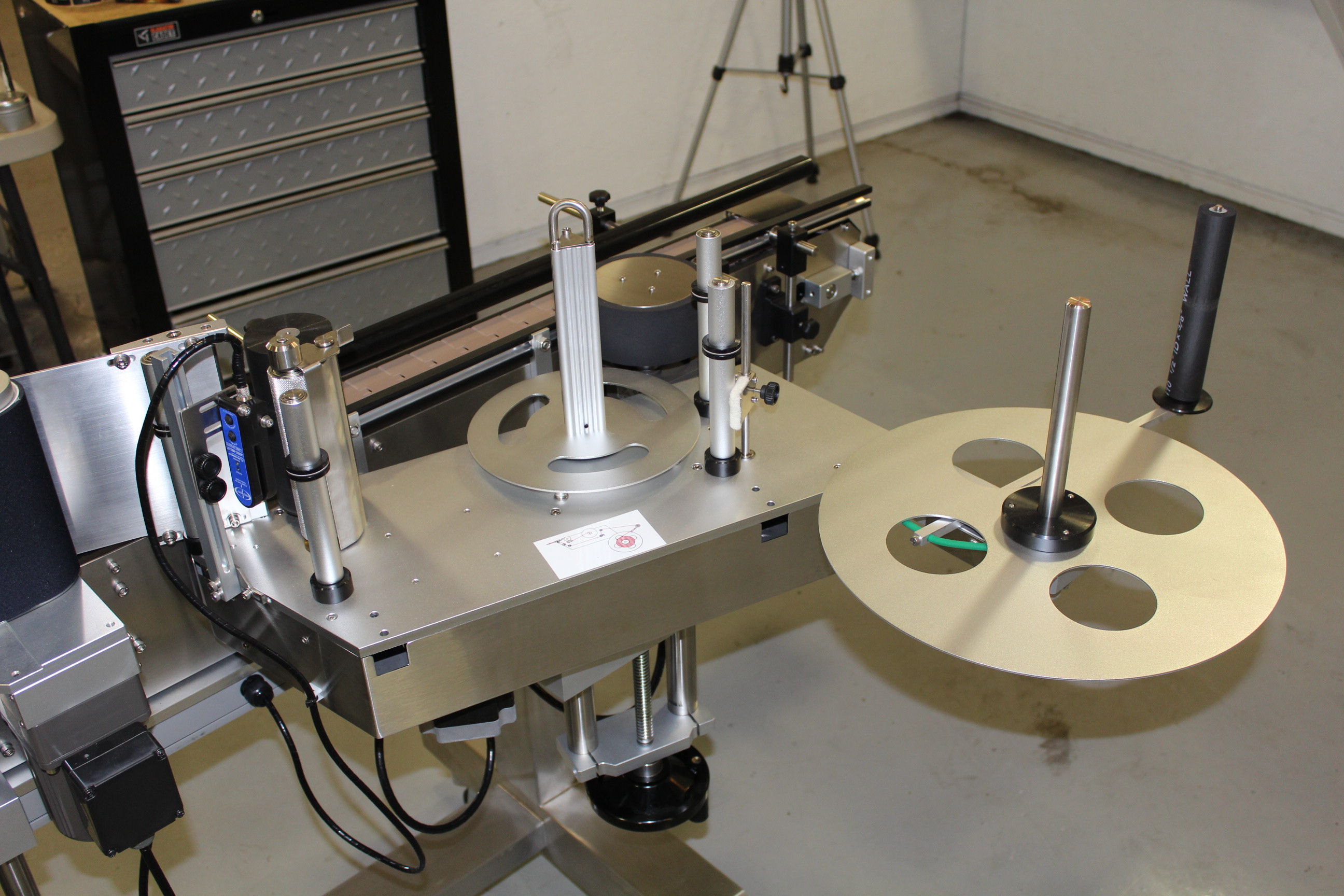

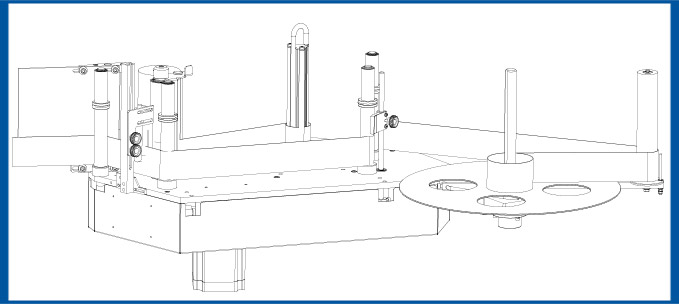

1. Place the label roll on the supply plate and pass the labels around the tension roller to control over rotation of the roll.

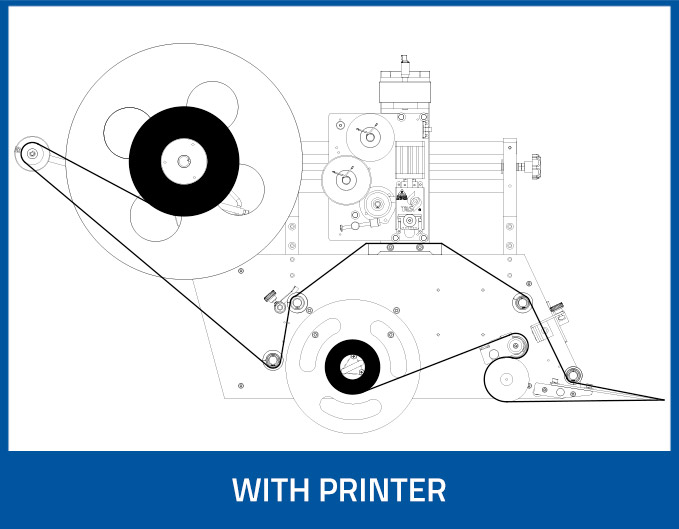

2. Secure the labels by adding tension to the label press pad. This will prevent the labels from running loosely.

3. If a printer is installed, pass the labels between the print head and the print pad of the printer.

4. It is important for the labels to pass through the forks of the label sensor and make contact with one side. The label sensor controls the dispensing of the labels.

5. The dispensing plates peel the label from the base paper and apply it to the products.

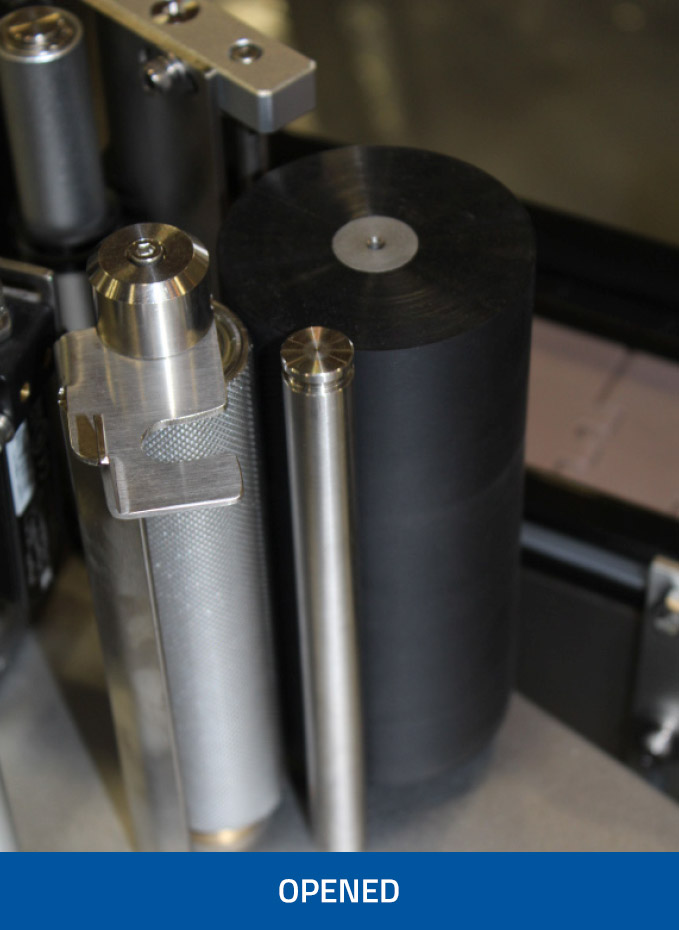

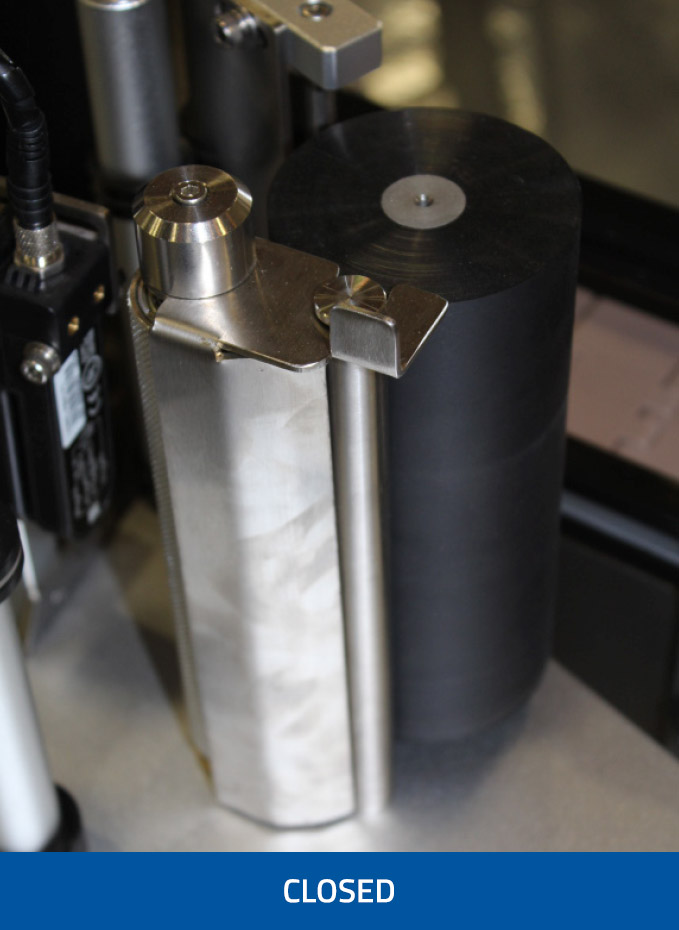

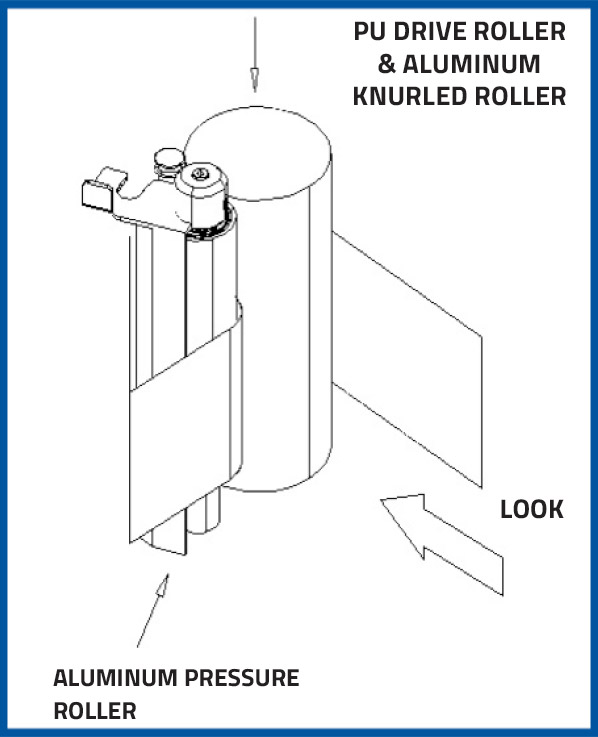

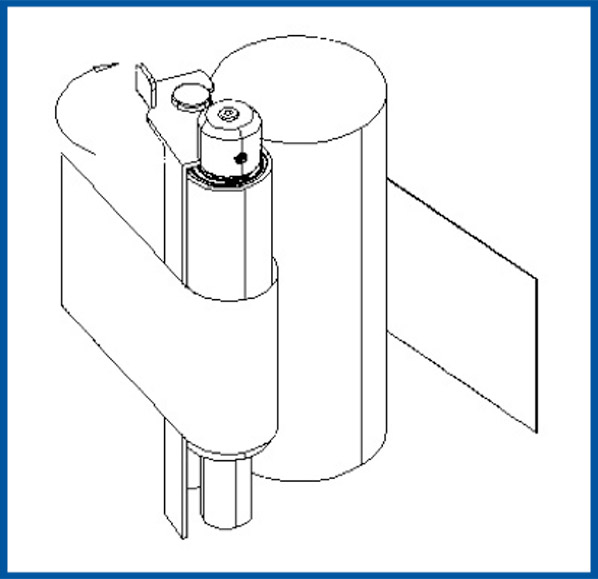

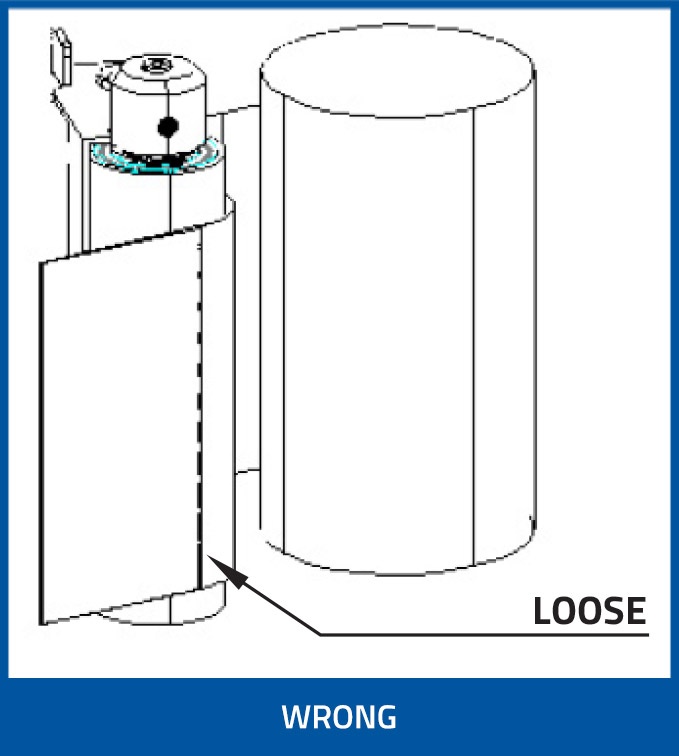

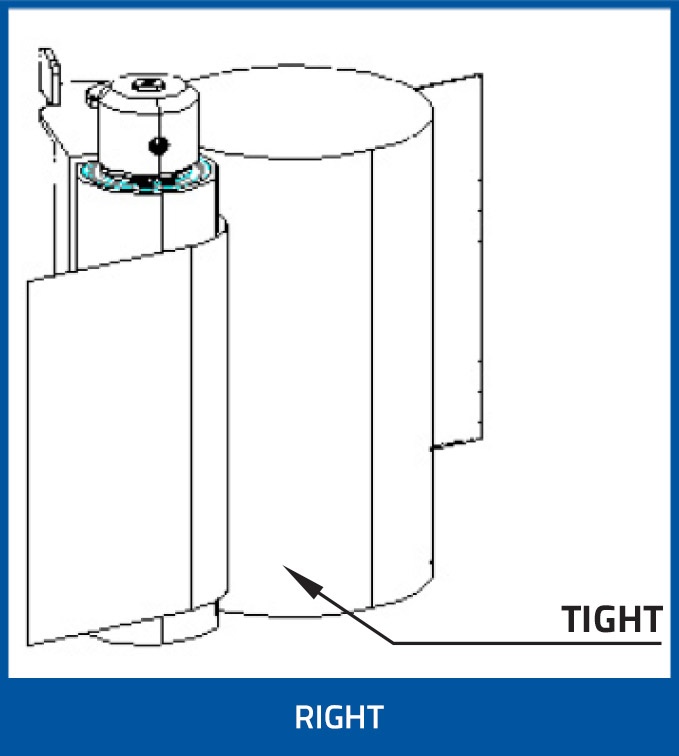

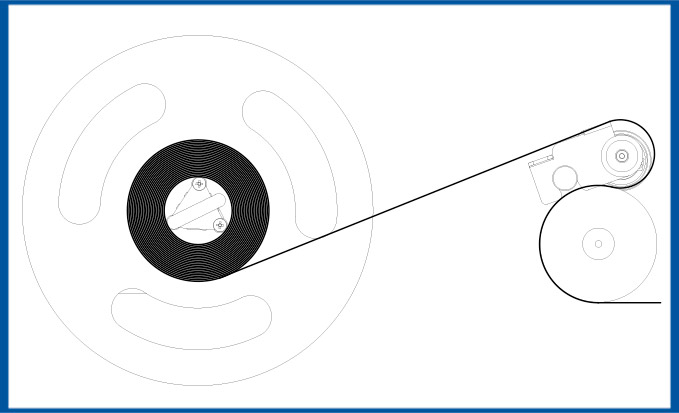

6. The PU drive roller pulls the base paper to apply the labels. The aluminum knurled roller must be closed and locked in place with the PU roller in order to squeeze the base paper and pull effectively. See below.

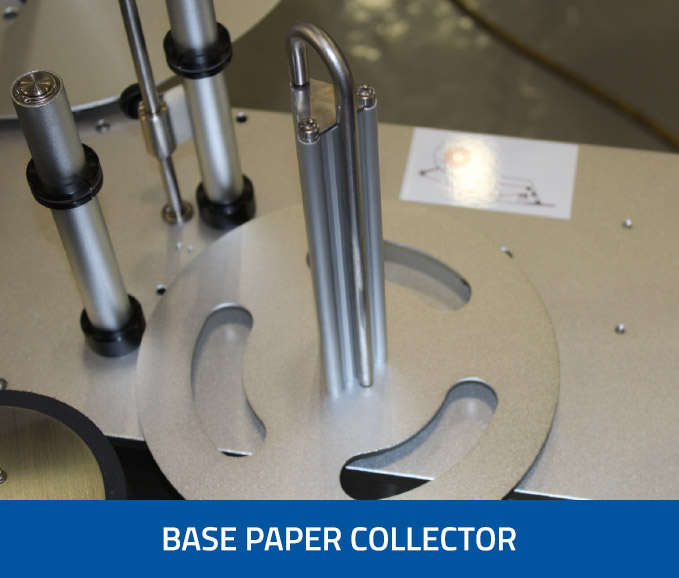

7. Remove the “J” hook on the base paper collector and wind the base paper around the triangular shaft. Then reinstall the “J “hook to secure the base paper and ensure proper pickup tension.