PL-221 Adjusting PU Drive Roller & Aluminum Knurled Roller

How to adjust the PU drive roller and the aluminum knurled roller

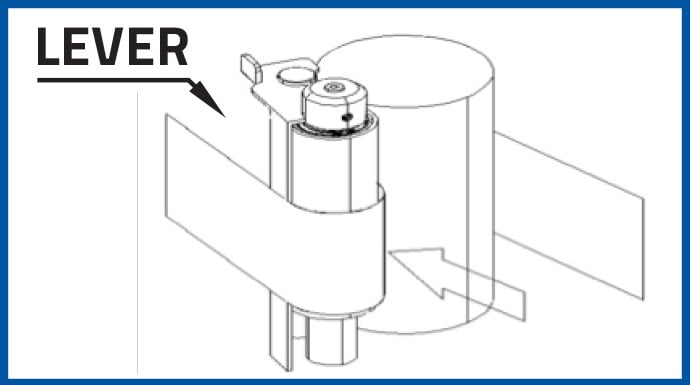

1. Turn on the power and then close the lever to make the aluminum knurled roller contact the PU drive roller.

2. Check in between the PU drive roller and the aluminum knurled roller to make sure that they are tightly making contact. (When the power is on, the PU drive roller is engaged with the stepper motor. If the lever is closed, the aluminum knurled roller should not spin freely.) If the contact is too tight proceed to step 3. If the contact is too loose proceed to step 4.

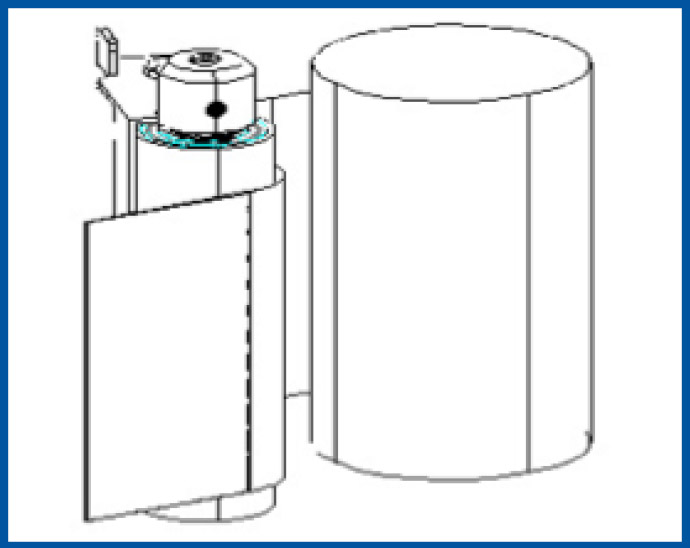

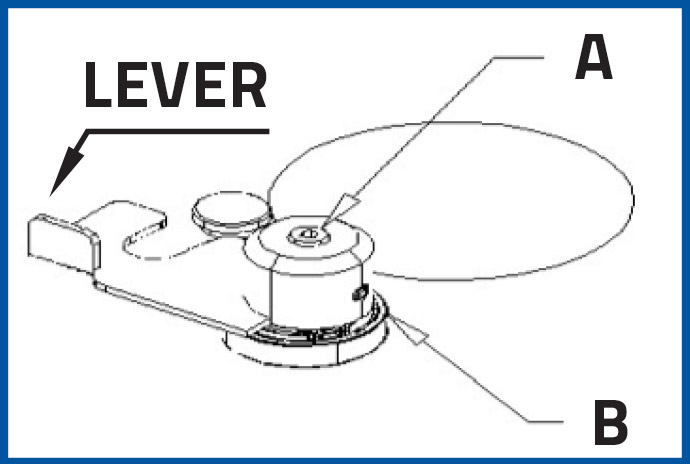

3. When locking the lever into the closed position, if the aluminum knurled roller presses too tightly against the PU drive roller, the PU drive roller will no longer be vertical. To correct this problem open the lever until the PU drive roller is vertical and the aluminum knurled roller is still making contact. Loosen the A&B set screws and close the lever into the locked position, then retighten the A&B set screws.

4. Loosen the A&B set screws then open the lever from the locked position. Retighten the A&B set screws and close the lever to the locked position. Check if the aluminum knurled roller is tightly making contact to the PU drive roller. If not, repeat step 4 again. If too tight, see step 3.

5. When the lever is locked into the proper position, check if the PU drive roller is moving along the aluminum knurled roller. If the contact is very tight that the PU drive roller is not vertical, pull back on the lever until the PU drive roller is vertical and the aluminum knurled roller is touching the surface of the PU drive roller. Then loosen the A and B screws and turn the lever to the proper lock position. Tighten the A & B screws.

6. Loosen A & B screws then pull the lever away from the fixed shaft. Tighten the A & B screws. Lock the lever and check if the aluminum knurled roller and the PU drive roller are pressed together correctly. If not, repeat this step again. If too tight, see step 5.

WARNING: If the aluminum knurled roller is not tightly pressed against the PU drive roller, the labeling will be inaccurate, which will cause incorrect labeling. If the aluminum knurled roller is pressed too tight, it will cause the PU drive roller to wear and crack.