PL-211 Object Sensor

How to adjust the object sensor

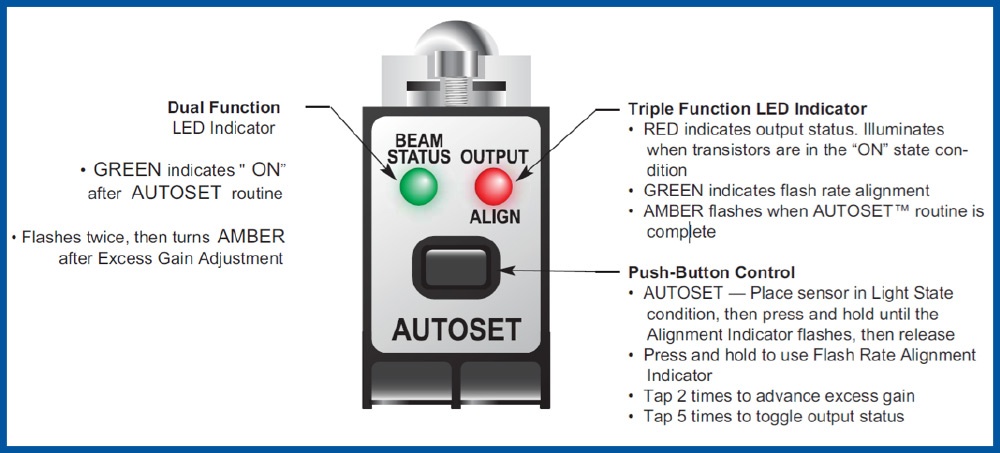

The object sensor is a fiber optic infra-red sensor use to detect the presence of bottle on the labeling zone. If the sensor is not able to detect a bottle, adjust the intensity of the amplifier until the sensor is able to trigger the applicator to apply a label.

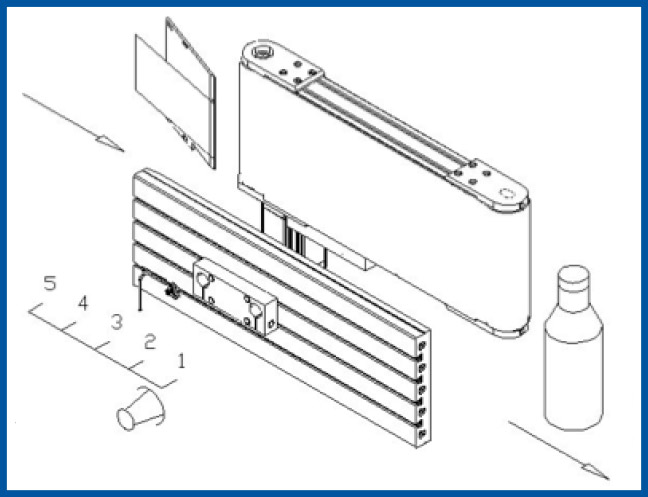

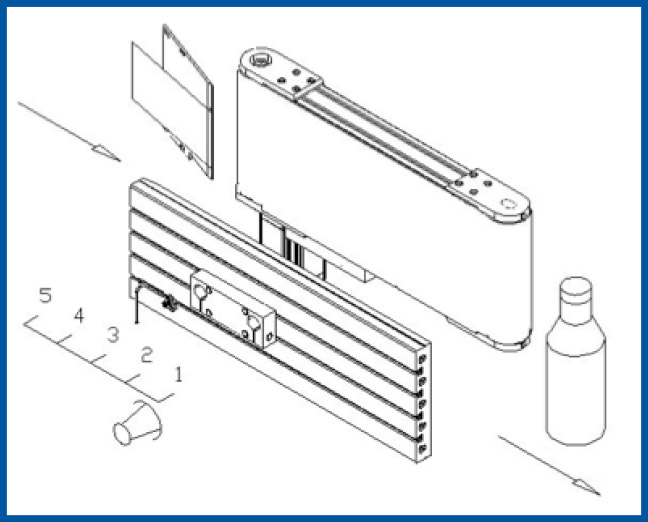

1. If sensor moves too far right, the label will come out too late and will not be applied to the bottle.

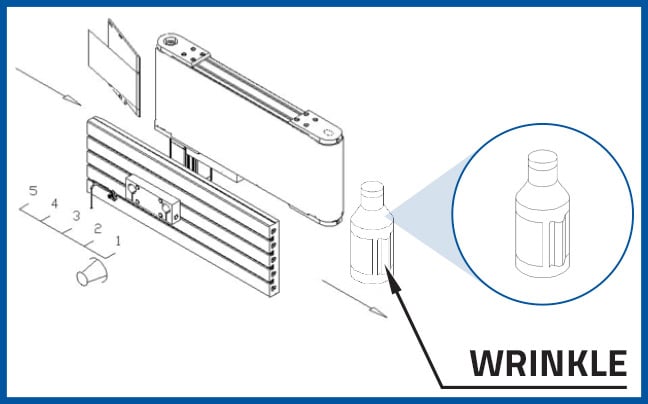

2. If sensor moves too far left, the label will come out too early and possibly cause vertical wrinkles.

3. The proper position of the sensor is to make sure the label is dispensed and applies to the apex of the bottles' surface.

NOTE: The label position can be controlled through the HMI using the label peel delay function.